Falling Film Evaporator

A shell and tube heat exchanger is divided into two compartments. It’s most basic function is to bring a heating or cooling fluid, called media, into indirect but intimate contact with a product fluid, called the process fluid. Energy, as heat, is transferred rapidly and efficiently across a shell & tube heat exchanger between the media and process fluids. When the goal is to use an S&T heat exchanger to evaporate a component of the process fluid, then the media is hotter than the process fluid, and energy is transferred into the process liquid from the media.

In the specific case of the falling film evaporator, the heating media is circulated through the shell side of the S&T heat exchanger. The process fluid is passed through the tube side of the evaporator. Energy is transferred from the heating media into the product, and a portion of the product is vaporized.

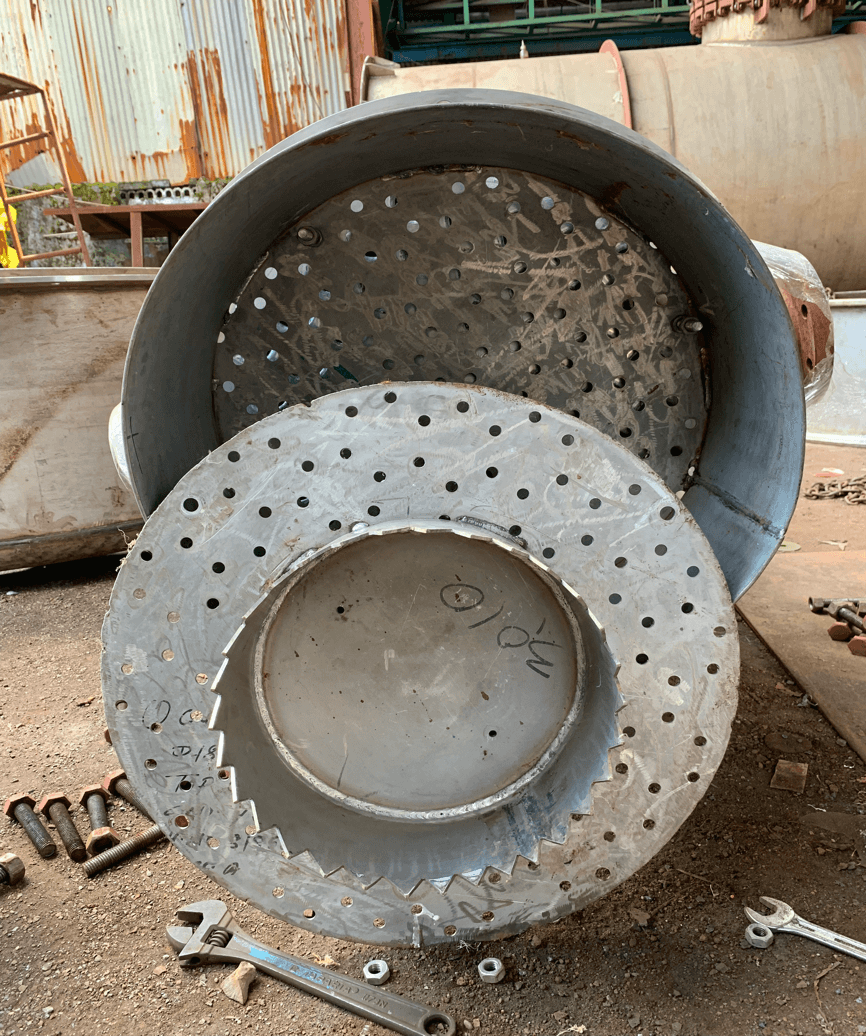

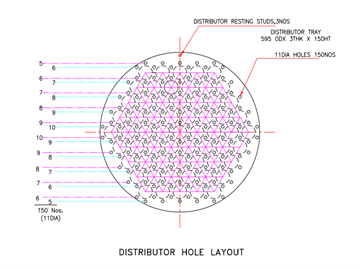

The process liquid is pumped into the top of the falling film evaporator and is distributed evenly across all of the heating tubes in the heat exchanger. It is very important that the liquid be well distributed so that it evenly flows down the inside walls of each tube. This film of liquid that is descending through the tubes is known as a “falling film” and is where this particular heat exchanger derives its name.

Need Urgent Supply? Enquire Now

We manufacture and export Falling Film Evaporator across the globe, we stock ready for urgent supplies.